The problem of ceiling mis-cuts and gaps around newly installed ceiling fixtures.

Have you recently replaced or installed a lighting fixture or ceiling fan in your ceiling and are left with an unsightly gap between the drywall, sheetrock or ceiling tile and newly installed fixture?

Have you recently replaced or installed a lighting fixture or ceiling fan in your ceiling and are left with an unsightly gap between the drywall, sheetrock or ceiling tile and newly installed fixture?

This is a common problem for many electrical, lighting installers, DIY’ers and homeowners. We see the gaps, rough edges and damaged drywall surrounding the new fixture occurring often when removing an older ceiling Hi-Hat fixture, can light, spot light and replacing with a new smaller LED Hi-Hat fixture. The advent of new LED energy saving and money saving fixtures has spurred a surge of lighting replacements. The new LED fixtures are usually smaller than the original incandescent or fluorescent fixture. Internet how-to videos will tell you to solve this problem by fixing and repairing the drywall with a paint and mud mixer, but this can be a difficult, expensive and extremely time-consuming task.

There are many other situations and installs where we see the problem of the gap in the sheetrock, larger than the fixture. The fire alarm installer, the fire sprinkler installer and speaker install companies often need a quick fix for an oversized ceiling hole, gap, or an ugly paint ring surrounding the newly installed hardware.

Luckily, there is no need for any excessive, expensive and time-consuming repair, as there is a solution that is just as easy as installing the fixture itself. The DIY video’s commonly seen describe the fix or repair while using drywall tape and spackle. Several coats to be applied along with sanding. Then of course a few coats of paint.

Another common problem that is easily fixed by a goof ring in the multi-layer rings of ceiling paint that surround the base of the old ceiling fixture. We have all seen it, how and when did that bumpy ring happen? The repair for paint rings is also multiple coats of spackle followed by sanding and painting.

There is a quick and easy solution for the aforementioned problems. Enter the custom cut goof ring or goof plate in white or black acrylic. Note; make sure the outside diameter of the ring is wide enough to cover the outer most paint ring on the ceiling.

What is a Goof Ring?

A goof ring also known as a trim ring, goof plate or a ceiling medallion is a custom cut white or black acrylic solution. There are also stock size goof rings and trim plates made of metal. The goof ring should be at least one inch wider in diameter than the actual fixture. It installs and rests between the fixture and the existing sheetrock, drywall or ceiling tiles. This solution can be used for new or replacement fixtures such as recessed can lights, Hi-hats, ceiling fans, chandeliers, spot lights, sprinkler heads, speaker plates or fire alarm sensors. It is a quick, easy, and inexpensive way of hiding unfinished edges for a multitude of ceiling applications. The size of a goof ring can be customized and made in several different shapes and colors so they can properly modify and adjust to your fixture whether it be a recessed light, speaker, fire alarm, or ceiling fan. The most popular custom trim plate or goof ring is round; however, a square plate can be produced as well as a round interior ring with a square outside trim. Whether the hole was cut incorrectly, the edges of the opening are jagged and unattractive, or you are replacing a ceiling application that is smaller than your previous one, a custom goof ring can help quickly remedy this problem. These ready-to-install white or black acrylic rings provide a convenient and attractive means for covering the edges of a mis-cut or an existing hole in the ceiling that is too large for the new fixture, electrical box, J-box. Great for hiding the gap when replacing with new LED’s made by Lithonia, Lotus, Lux rite, Satco, Nicor, Halo, commonly found in Home Depot or Lowes. We also see the need for goof plates on wall applications covering mis-cuts behind electrical outlets, fire alarm key-pads and light switches.

A goof ring also known as a trim ring, goof plate or a ceiling medallion is a custom cut white or black acrylic solution. There are also stock size goof rings and trim plates made of metal. The goof ring should be at least one inch wider in diameter than the actual fixture. It installs and rests between the fixture and the existing sheetrock, drywall or ceiling tiles. This solution can be used for new or replacement fixtures such as recessed can lights, Hi-hats, ceiling fans, chandeliers, spot lights, sprinkler heads, speaker plates or fire alarm sensors. It is a quick, easy, and inexpensive way of hiding unfinished edges for a multitude of ceiling applications. The size of a goof ring can be customized and made in several different shapes and colors so they can properly modify and adjust to your fixture whether it be a recessed light, speaker, fire alarm, or ceiling fan. The most popular custom trim plate or goof ring is round; however, a square plate can be produced as well as a round interior ring with a square outside trim. Whether the hole was cut incorrectly, the edges of the opening are jagged and unattractive, or you are replacing a ceiling application that is smaller than your previous one, a custom goof ring can help quickly remedy this problem. These ready-to-install white or black acrylic rings provide a convenient and attractive means for covering the edges of a mis-cut or an existing hole in the ceiling that is too large for the new fixture, electrical box, J-box. Great for hiding the gap when replacing with new LED’s made by Lithonia, Lotus, Lux rite, Satco, Nicor, Halo, commonly found in Home Depot or Lowes. We also see the need for goof plates on wall applications covering mis-cuts behind electrical outlets, fire alarm key-pads and light switches.

How to Install a Goof Ring?

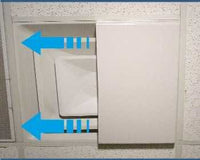

Installing a goof ring is just as simple as the initial installation in your drywall or tile ceiling by placing the goof ring on top of the ceiling fixture, can light, speaker, fire alarm, ceiling fan and feeding the wires through the trim ring and simply install the new fixture in place as one component, thereby sandwiching the goof ring between the new fixture and the ceiling, resulting in the flange of the goof ring covering and concealing the gap between the drywall or tile and the newly installed ceiling application. It’s important to note that the goof ring or goof plate does need mechanical support or screws, it is simply designed to be sandwiched in between the replacement fixture and the ceiling.

How do I Purchase the Right Size Goof Ring?

A round, square or round-in-square custom goof ring has two measurements: an outside diameter (OD) and an inside diameter (ID). The outside diameter is the size in inches of the entire ring, from furthest point to furthest point. The outside diameter is NOT just the size of your desired flange. The inside diameter of the goof ring is the size in inches of the inner hole that is needed to allow wiring and mounting hardware to pass through the inner ring. Note; at no point should the inner diameter be larger than the outside diameter of the actual fixture that you are installing. Something that is important to note is that the width of the flange or rim of the goof ring will be the difference between the outside diameter and inside diameter, divided by 2.

Let’s explain, a goof ring with an outside diameter of 10” and an inside diameter of 6” will have a 2” flange/rim.

10” OD - 6” ID = 4” divided by 2 = 2”.

Let’s do another one, 11-1/2” outside diameter with an inside diameter of 8” will have a flange/rim of 1-3/4” wide.

11.5” OD - 8” ID = 3.5” divided by 2 = 1.75”.

We suggest the width of the flange/rim should never be less than ½” wide.

Goof Rings and Goof Plates can be custom cut to a small as a 2” outside diameter and as large as 23-1/2 outside diameter.

Homeowners and DIY’ers will feel confident knowing the solution for mis-cuts and larger ceiling gaps can be fixed with as little as one custom cut goof ring. The contractor will be confident that their install job of 10, 20 or 1000’s of ceiling fixtures will go smoothly and quickly when the correct size goof ring is ordered in advance of the install project.